It all started with ship nails

But back when the hammers first started working, ship nails were the main product. The hand forged nails quickly became known for their premium quality and were exported far beyond Swedish borders for example Spain and Portugal, just like our axes came about to be, centuries later.

When Jakob Renstierna died 1716 his widow Magdalena Toutin-Reenstierna took over the forge. She in her turn sold it 1732 to the widow Brigitta Wallrave von Berchner that later died in 1745 and her granddaughter Maria Eleonora Strahlenberg came to inherit the forge. At the time the forge manufactured mainly nails, spades and axes.

Everything between waffle irons and rail cars

Over the centuries Hults Bruk expanded into a wide range of items such as forged metal sheets and anchor chains, castings of furniture and stoves, waffle irons and other small everyday use articles, followed by axes and spades used by farmers in the region for work in the forests and in the fields. In the late 1800s even railcars were manufactured at Hults Bruk.

After a couple of different owners Magnus Lorentz Ekelund bought the forge all together in 1818. He managed to build a small village around the forge and established a school for the children of the workers in the forge. The teacher was paid for by the forge. The wind of change had started and it was Magnus Ekelunds’ son Gunnar Ekelund that soon came to be the major change for the forge.

The age of the axe and Gunnar Ekelund

By the 1870s axes had become a major part of Hults Bruk’s production. This was a turbulent period when the Industrial Revolution brought changes across Europe. As a result of major developments in all facets of society the demand for forestry products grew and with that so did the demand for axes.

The owner of Hults Bruk at the time, an ironmaster named Gunnar Ekelund, ventured to America. He brought back not only new production techniques, but also hickory handles and axe designs such as Montreal and Yankee patterns. With time these became some of our most popular and enduring axe models.

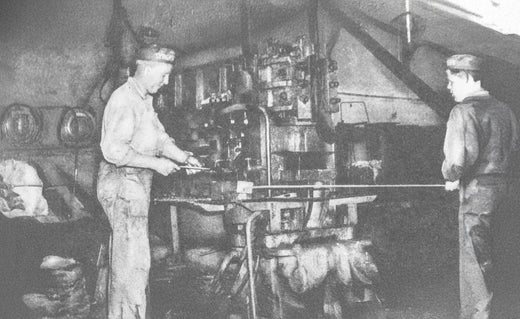

He also bought two new axe forging machines in 1877 to meet the demand. Over time the reputation of Hults Bruk axes grew and during the 20th century they were exported all around the world. Hults Bruk was actually represented in the 5th World Exhibition in Wien 1873.

Hults Bruk axes around the world

Hults Bruk axes have been sold under several different names such as “Flecha” in South America, “Jarrah Jack” in Australia and “Tiger” in South East Asia. But with time Agdor came to stand out as the most widely distributed, enduring brand and has been a mainstay of the Hults Bruk axe range for nearly 100 years. The classic Agdor range was inspired by traditional North American axe patterns of the late 19th entury. In a time when axes were the most important tools for the logging industry, Agdor axes became the preferred choice for lumberjacks around the world. Agdor axes were chosen for the outstanding quality of the steel and forging. The Agdor brand of axes became especially popular in regions with hard and difficult wood, and woodsmen would pay up to a month’s wages or more for an Agdor axe that was made on the other side of the globe.